Is there a difference?

By Rick Stier

Fifty years ago, Dr. C.J. Robertson published an article in Food Technology magazine that listed five basic elements for maintaining frying oil. Even though this is an old publication, these five principles remain the same. Dr. Robertson’s basic principles for quality frying were introduced in an article prepared for Restaurant Facility Business magazine in October 2015. These may be old, but they still apply in today’s world. They are:

1. Proper design, construction and maintenance of equipment.

2. Proper operation of equipment.

3. Minimize exposure to ultraviolet (UV) light.

4. Keep salt and other metal sources away from the oil.

5. Filter regularly.

Element Number 5, “filter regularly,” is something that is done by most fryer operators at both the foodservice and industrial level. But do people really understand what they are doing or how their filtration system works? Filtration is an essential element but it is not a panacea for oil management. Once oil begins to degrade, the process is irreversible. No amount of treatment or manipulation can bring it back to what it was before the heat was turned on and food introduced to the fryer. The key to managing oil quality is incorporation of each and every one of these elements, but filtration can play a huge role in extending oil life. Dr. Glen Jacobsen of the Campbells Soup Company mentioned that one of the roles of filtration was removal of particulates. Particles remaining in the oil can adhere to heating elements, which could impede heat transfer. They will also serve as a reactive site for oil degradation. In addition, as particulates remain in a fryer, they continue to darken and may affect the appearance and overall taste of a food.

Dr. Michael Blumenthal proposed the terms active and passive filtration as a means of differentiating the basic mechanisms for filtering oil. Passive filtration describes systems that simply act as sieves or filters; they only remove suspended solids or particulates from the oil. Up until the 1980s, almost all systems were passive. On the other hand, an active system not only acts as a sieve to remove particulates, but also removes chemical components from the oil. In other words, an active system will remove components from oil that are non-filterable. The mode of activity varies with the system but may include chemical reactions in which materials in the oil are chemically bound to the treatment media, molecular entrapment or physical means in which materials in the frying oil are bound to the adsorbent in the system. Some now differentiate active and passive filtration through the use of the terms filtration and treatment.

Dr. Michael Blumenthal proposed the terms active and passive filtration as a means of differentiating the basic mechanisms for filtering oil. Passive filtration describes systems that simply act as sieves or filters; they only remove suspended solids or particulates from the oil. Up until the 1980s, almost all systems were passive. On the other hand, an active system not only acts as a sieve to remove particulates, but also removes chemical components from the oil. In other words, an active system will remove components from oil that are non-filterable. The mode of activity varies with the system but may include chemical reactions in which materials in the oil are chemically bound to the treatment media, molecular entrapment or physical means in which materials in the frying oil are bound to the adsorbent in the system. Some now differentiate active and passive filtration through the use of the terms filtration and treatment.

Kubose described three of the basic processes by which frying oils are filtered. These are absolute filtration, depth filtration and adsorption. The first two processes are examples of passive filtration. The latter is one of the means by which active systems or oil treatments work.

There are active materials imbedded in the filter media that remove oil degradation products, such as free fatty acids (FFA), oil oxidation by-products, and other select decomposition products. In these systems, an interaction occurs between the filter material or component of the filter material, and a particulate or compound within the frying oil. The particulate or compound(s) are then bound to the filter. This allows removal of minute oil insoluble particulate and even specific molecules. Adsorption is only a physical phenomenon whereas chemical reactions involve actual bonding of oil degradation products to the filter media. Physical adsorption involves weak intermolecular forces whereas chemical absorption involves the formation of a chemical bond between the active material and a soluble component of the oil. Adsorbents such as carbon attract materials, such as chlorophylls and carotenes, found in both crude vegetable oil and in used fryer oils. The properties of the carbon can be modified via activation processes that can also include treatment with either acids or alkalis. This can alter the adsorbent properties of the carbon transforming the product into an effective agent for chemisorption mentioned earlier.

One of the most important benefits of active filter media or treatments is the removal of soaps. Soaps form in oil as follows:

Reaction of Free Fatty Acids with Metals

CH3(CH2)7CH=CH(CH2)7C=OH + Na+Silicate (SODIUM SILICATE)

(OLEIC ACID) ||

O

|

| H2O

V

CH3(CH2)6CH2CH=CHCH2(CH2)6C-ONa (SODIUM OLEATE)

||

O

Metals from foods are leached into the oil and react with free fatty acids in the presence of water to form the soaps. Soaps, water and metals will all damage oil, so removing these is a key element for extending oil life.

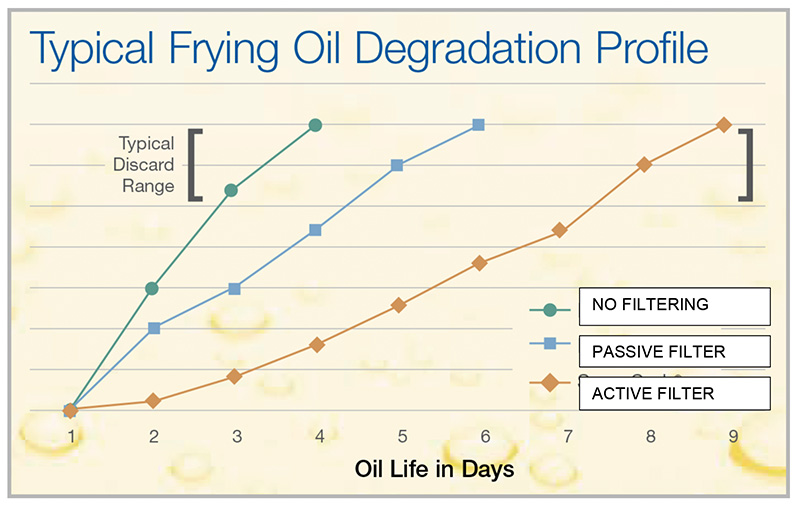

The bottom line is that using a passive system or oil filtration system is better than not filtering at all, but adopting an active system or an oil treatment as part of an oil management program is the best option. Figure 1 shows how these three elements compare. Passive systems will only remove particulates, but an active system can remove a wide range of compounds depending upon how it is formulated. Of course, the key is selecting the best active system for your operation, working with the supplier to properly set up the system and then maintaining that system as designed.

REFERENCES

Blumenthal, M.M. (1991), “A New Look at the Chemistry and Physics of Deep Fat Frying,” Food Technology, 45:2, p. 68 – 71, 94.

Jacobsen, G.A., (1991), “Quality Control in Deep-Fat Frying Operations,” Food Technology, 45:2, p. 72 – 74.

Kubose, D. (1990), “Oil Maintenance and Care”, Presented at Deep Frying of Foods, University of California at Davis, May 16-18.

Robertson, C.J., (1967), “The Practice of Deep-Fat Frying,” Food Technology 21:1, 34 – 36.

— Rick Stier is a consulting food scientist experienced with frying oil and frying oil programs. Stier helps foodservice operators develop safety, quality and sanitation programs with the goals of increasing profits for the establishment. He is a contributing editor for Food Engineering. Stier has been a scientific advisor to Filtercorp for the past 25 years.