Construction webcams simplify management of interior buildouts.

By J.P. Schaaf

Interior retail buildouts are among the most expensive construction projects, with cost per unit area far exceeding that of an exterior build. And they can be more logistically complex. Coordination of multiple trades and the on-time delivery of materials, fixtures and products are key to ensuring quality, containing costs and avoiding delays. The use of interior construction cameras is gaining popularity for all those reasons.

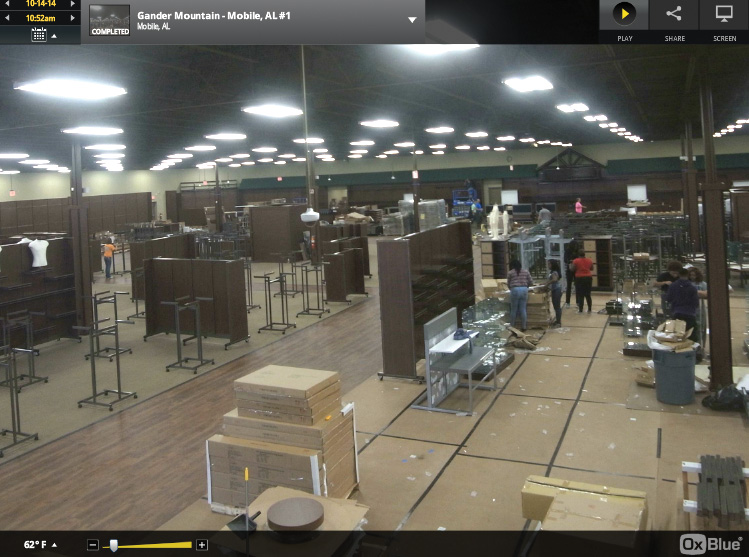

On any given day, Dustin Rassbach, Gander Mountain’s construction project manager, oversees several projects from east of the Rocky Mountains to upstate New York. Gander Mountain Company operates the nation’s largest retail network of stores for hunting, fishing, camping and marine products and accessories. In 2014, the company opened 23 stores nationwide, and nine more will be completed by the end of 2015. Interior and exterior construction cameras help him do his job without the need for multiple site visits.

On any given day, Dustin Rassbach, Gander Mountain’s construction project manager, oversees several projects from east of the Rocky Mountains to upstate New York. Gander Mountain Company operates the nation’s largest retail network of stores for hunting, fishing, camping and marine products and accessories. In 2014, the company opened 23 stores nationwide, and nine more will be completed by the end of 2015. Interior and exterior construction cameras help him do his job without the need for multiple site visits.

“We have one exterior fixed position camera placed at an angle to see two sides of the building. As soon as we have a roof on, we put a camera inside the building, and it stays there until 2 days before we open the store,” says Rassbach. “The cameras allow us to share information very easily with our vendors and management teams. And they certainly reduce our workload because we don’t have to provide weekly updates with pictures from our general contractors to our management teams. Everyone can see where the store is at without having to ask the question, ‘Where are we at with that store?’”

Rassbach was familiar with using exterior construction cameras to capture ground-up construction, and when he joined Gander Mountain in 2012, he started using webcams to capture interior buildouts. Everyone on the project team has access to the cameras throughout the project, from the design team to the project contractors and vendors. When all stakeholders and decision makers have access to the same information — the same images and time-lapse movies — issues and inquiries get resolved faster. This goes a long way in avoiding delays and keeping the project on schedule. For a retailer whose new store might do thousands of dollars of sales per day, opening on time, even ahead of schedule, is an appealing value proposition.

Remote Monitoring Optimizes Travel to the Jobsite

Designers, vendors, project managers and owners all need to stay abreast of what’s happening with a project. Every visit to the jobsite, however, adds to the cost of the job in terms of both time and money. Construction webcams reduce those costs by providing 24/7 remote jobsite visibility. Stakeholders can view the jobsite in real time, review images that document every moment of the buildout, and watch up-to-date time-lapse movies to track sequencing of events. Teams that are far from the site and from each other can monitor progress and quality and easily communicate any issues among themselves and with crews on the ground.

“Everyone can see the store and watch as the schedule comes together. Global communication is so much better when you have visuals. And as we progress through the schedule, more people gain access to the cameras, all the way to our fixture teams toward the end,” says Rassbach. “The cameras help us identify potential issues and obstacles as they come up. We can also monitor and work with our vendors without having to be onsite. Instead of traveling six or seven times to the jobsite, we can make one or two visits and still manage construction based on the camera images.”

Duane Boris, director of real estate development at Northern Tool + Equipment, uses multiple cameras that are interchanged for interior and exterior use. Northern Tool + Equipment has 92 retail locations offering tools and equipment for to do-it-yourselfers, contractors and professional shops.

“For us, the cameras are critical,” says Boris. “We operate with a lean staff and we can’t be onsite as much as we’d like, so being able to monitor progress from the office and on the road using the desktop (dashboard) and phone app is great.”

“For us, the cameras are critical,” says Boris. “We operate with a lean staff and we can’t be onsite as much as we’d like, so being able to monitor progress from the office and on the road using the desktop (dashboard) and phone app is great.”

Errors Can Be Caught & Corrected Early

Even with close attention to detail, mistakes happen. With so many eyes on the project, however, they’re more likely to be discovered and corrected early.

Boris and his team find the construction cameras useful for tracking what’s happening onsite against the construction schedule. “A vendor may say that lights have been installed, but you’re looking at the cameras, and they haven’t been installed yet,” he says. “It allows us to be proactive as far as holding our contractors and vendors accountable.”

“I’ll bet you we catch 15-20 mistakes per project with the cameras,” adds Rassbach. “We had a contractor that was installing flooring at the incorrect location. We’ve had painters using the wrong colors. By looking at the camera we could see those mistakes and correct them immediately.”

Tracking Progress Facilitates Just-in-Time Delivery

Workspaces on interior projects can be hectic and crowded, with several trades — each with several crew members — all working at once. The risk of accidental damage to building materials, fixtures and product is minimized when they’re not onsite until needed. Regular progress monitoring via a construction webcam allows planners to schedule deliveries and coordinate installation according to the pace of the project. This not only protects materials (and workers); it also makes for a neater, more efficient workspace.

Know What To Look For in an Interior Camera

When considering what type of camera to use for capturing interior construction, start with a system that captures high-resolution still images. Six mega-pixels or higher is ideal. Video and/or security cameras are grainy and do not provide the clarity required to view fine line details like paint color, flooring type, possible damage to fixtures or other key physical elements.

Also, the camera should be easy to mount and move around to follow the interior buildout action. Consider the weight of the camera, as well. Many exterior construction cameras weigh as much as 15-30 lbs., owing to their rugged durability. An interior construction camera can weigh as little as 5 lbs. Interior cameras can be mounted three different ways: to a wall, from the ceiling by a hook mount, or on a tripod, which allows for easy movement.

Camera placement is also key to success. Start with the floor plan to determine ideal camera placement for optimal visual documentation. A construction camera professional can also make placement recommendations based on staging (the sequence and location of materials and fixtures), lighting and access to electricity.

— J.P. Schaaf is an account executive with OxBlue Corp., a leading provider of construction camera systems used by construction professionals and project owners since 2001 to monitor and manage jobsites around the world.