The future of your kitchen tools is in your hands.

By Erik Koenig

Your equipment is down and the dinner hour is upon you. If the fryer, range, oven or other key items you depend on don’t work, you don’t deliver.

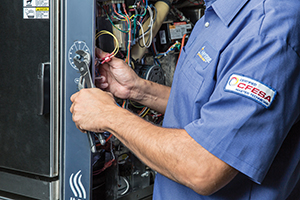

While most of the time you may need an expert to come in to replace the damaged part, there are opportunities to fix some issues yourself. These simple fixes can be tackled without having to call a service technician and can keep you ahead of the game as part of an effective preventative maintenance program.

Being proactive and staying on top of minor repairs is a win-win, for both the operator and equipment manufacturers. Maximizing equipment performance helps you deliver the highest quality product as well as protecting warranty and certifications, including UL and NSF. For manufacturers, perception is reality and when equipment is working at its optimum levels, the likelihood of a “like for like” replacement increases.

There are many advantages to making simple repairs at the operator level, including performance, cost savings and ultimately customer satisfaction. For the aftermarket parts industry, the ability to deliver quality genuine manufacturer produced parts and valuable information creates a true partnership dedicated to keeping you productive — no matter who is making the repair.

There are many advantages to making simple repairs at the operator level, including performance, cost savings and ultimately customer satisfaction. For the aftermarket parts industry, the ability to deliver quality genuine manufacturer produced parts and valuable information creates a true partnership dedicated to keeping you productive — no matter who is making the repair.

Let’s take a look at key reasons you want to look at your kitchen equipment and the value of tackling some simple repairs yourself:

Equipment Performance

There are many advantages to maintaining the performance of your equipment before it breaks down. Every piece of kitchen equipment you own has small parts that can wear out or may not be delivering optimal performance for you. For example, you may not think a knob is important, but if it is not installed correctly or is wearing out, it may be causing you to overcook or undercook food since you can’t accurately control the temperature you need. This can result in food that is not pleasing and you could lose a customer or, even worse, serve undercooked food that could cause illness. And it doesn’t have to be extenuating circumstances that cause a tool to fail. Just normal use and wear and tear can lower efficiency. You can also select when you want to do preventive maintenance, which is a much better scenario than something failing during your peak hours and your kitchen comes to a halt while the repair is being made.

Cost Savings

There are cost savings and satisfaction associated with knowing that you can fix something yourself. Using the knob example from above, the part can retail for $20 but also can play a critical role in performance. Performing the repair yourself can potentially save you up to $150 for travel, onsite and truck charge as part of a service call.1

Value Your Service Technician

Value Your Service Technician

Service technicians are true repair experts, working with both expensive and potentially dangerous kitchen equipment. Their time is valuable but for some operators, making the fix themselves can be perceived as encroaching on the technician’s livelihood. For a small repair like a knob, most service agents consider this type of repair a minor issue and likely may not have the part on their truck to begin with — opening the door for a return visit. Consult with your service provider and you might be surprised which repairs around your kitchen they would be comfortable having an operator make, freeing up service techs for the larger, more technically involved repairs they are highly trained to perform.

Here are a few examples of parts/equipment that you can review to determine if a simple fix can help you increase efficiency and effectiveness of the part and possibly your entire operation:

- Ovens: gas hoses, knobs, thermostats, grates, light bulbs

- Refrigerators: gaskets, handles, light bulbs

- Ice machines: air filters, water filters

- Steam tables: knobs, elements, thermometers, infinite controls

- Slicers: blades, sharpening and honing stones

- Can openers: blades, gears, switches

Easy access to aftermarket parts for your kitchen is imperative to your success. Working directly with manufacturers, service providers and end-users, your aftermarket parts supplier should identify areas to streamline the repair process, provide access to detailed information and deliver solutions that more efficiently and proactively accommodate rising customer expectations.

Your end goal? Look to even the smaller elements of your kitchen or workspace to save you time and energy and optimize the performance of your equipment.

1 These charges are typical of a service call and reflect 30 minutes travel, 30 minutes onsite and a truck charge.

— Erik Koenig is the director of marketing for Fort Wayne, Indiana-based Heritage Foodservice Group, a leading provider of 100% genuine OEM replacement parts and authorized aftermarket service for commercial and institutional kitchen equipment. Email the author at [email protected].