— By Paul Bothner —

Proper water heater selection impacts your restaurant’s bottom line.

As the restaurant industry reopens its doors after the national shutdown, owners are even more focused on improving operating profits. One area of evaluation needs to be the generation of hot water, as it is among the largest — and, in some cases, the Number 1 — energy consumer of all installed appliances within hospitality facilities, particularly restaurants.

Paul Bothner, PVI Industries

For this reason, higher efficiency, condensing water heater designs comprise the majority of installations on new construction projects, as well as current retrofits. This trend is expected to continue due to the rapid payback of the technology compared to older less efficient units.

Restaurant owners need to select a water heater based on more than “banner specs” such as efficiency rating, however. Three other factors to evaluate are footprint, materials of construction, and controls to get the best return on investment (ROI) and lower operating costs.

Smaller Footprint = Bigger Revenue

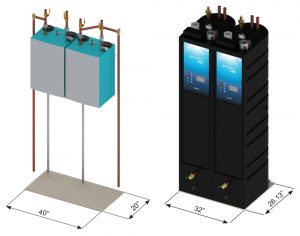

Perhaps the biggest trend is the need for larger BTUs in a smaller water heater. Restaurant owners are looking for units that deliver the necessary capacity in a more compact footprint. By minimizing the space occupied by the water heater, more square footage can be dedicated to revenue-generating operations. Adding an extra table or two can bring in additional dollars.

While some may consider wall-hung units as an alternative, they could actually prove to be less efficient. There are now water heaters that are so compact that they occupy less space tha n wall-hung units (see photo at left). These ultra-compact water heaters also have zero-side clearance capability to create a redundant system in the same space of a single tank water heater.

n wall-hung units (see photo at left). These ultra-compact water heaters also have zero-side clearance capability to create a redundant system in the same space of a single tank water heater.

Another hidden cost factor associated with wall-hung units is their propensity for temperature fluctuations. To offset this variable, water tube instantaneous heaters are often installed with a storage tank in high-demand commercial applications, such as larger restaurants. Additional space is, therefore, required.

There is another cost associated with such a system. The “instantaneous” nature of the product vanishes, as the operation changes from responding to variations in flow and adjusting burner firing rate accordingly to simply reheating the tank at high fire as quickly as possible between demands. This configuration lowers the efficiency of a water tube product due to its limited ability to modulate and the ever-increasing entering water temperature as the tank returns to set point. The result is increased operating expenses.

Advanced Controls for More Intelligence

There is a greater trend towards smart and connected water heaters. Throughout the restaurant and hospitality industry, the introduction of systems with advanced operating controls that incorporate cloud-based Internet of Things (IoT) technology are creating significant cost efficiencies by lowering operating and maintenance costs.

Real-time monitoring and fault alerts of the water heating equipment are becoming more commonplace. This new level of immediate intelligence results in more accurate maintenance prediction to control expenses on system upkeep. Immediate data access and analysis also improve troubleshooting to reduce the possibility of costly downtime for a restaurant.

Advanced Materials of Construction

The open-loop design of water heaters creates reliability and maintenance challenges. The water entering the restaurant is directly fed into the water heater, creating an aggressive environment. For these reasons, the materials of construction of the water heater are critical.

Certain units today (see photo at right) have a duplex stainless-steel construction with performance-enhanced, high-efficiency firetubes. This strong and highly durable design is resistant to aqueous corrosion in potable water at any temperature. It also significantly reduces chloride stress corrosion cracking. There is no need for tank linings or anode rods, which both require service over time. This eliminates the 3- to 4-year replacement cycle — and associated costs — common to glass-lined water heaters.

Certain units today (see photo at right) have a duplex stainless-steel construction with performance-enhanced, high-efficiency firetubes. This strong and highly durable design is resistant to aqueous corrosion in potable water at any temperature. It also significantly reduces chloride stress corrosion cracking. There is no need for tank linings or anode rods, which both require service over time. This eliminates the 3- to 4-year replacement cycle — and associated costs — common to glass-lined water heaters.

A fire tube heater is less prone to scale performance issues and is easier and less costly to maintain compared to a wall hung unit. Water tube instantaneous heaters contain narrow water pathways and are prone to hard-water scale buildup in the heat exchanger. Over time, water heater performance is reduced, requiring regular descaling, especially in high-volume commercial applications such as restaurants.

Other Cost Saving Moves

While footprint, advanced controls and materials of construction are three key factors, they are not the only ones. Restaurant owners should also evaluate the following:

- Hot Water Delivery at Temperature: A water tube instantaneous heater has a limit when it comes to providing hot water. If hot water demand occasionally outpaces the BTU input to the heater, the outlet water temperature will drop. For example, one 199,000 BTU wall-hung heater is not always capable of delivering enough flow at temperature. Such a limitation requires some foodservice establishments to install two or more wall-hung water heaters in locations where proper outlet temperature is mandated.

To avoid this scenario and the associated capital expense, new ultra-compact water heaters are designed with a water buffer. It serves as a reserve bank of water at the needed temperature for instances when hot water flow requirements exceed the recovery of the burner. Fewer units are required to meet the total hot water demand with these models.

- Effect of a Re-circulation Line: Certain fire-tube water heaters now have a dedicated recirculation fitting that re-introduces hot return water to the hot zone of the water heater. A cold-water zone at the bottom of the tank is unaffected, thereby “super cooling” the flue products to extract maximum energy from the condensing process. The result is continuing high efficiency on calls for heat.

This is more cost-efficient than installing a wall-hung unit. Water tube instantaneous heaters suffer an efficiency drop when a building re-circulation line is connected to the cold water inlet. Hotter water entering what is intended to be a cold water inlet directly impacts the heat transfer ability of any heat exchanger and increases operating cost as efficiency drops.

Conclusion

Restaurant owners have always strived to optimize performance and save on operating costs. That focus has become even more vital for success moving forward amidst COVID-19. By concentrating on factors such as the water heater footprint, its advanced controls and the materials of construction, operating costs can be significantly reduced, helping improve a restaurant’s bottom line.

— Paul Bothner is director, hot water solutions, for PVI Industries, a WATTS Brand. He has more than 30 years’ experience in the water heating market.