— By Jay Fiske —

IoT & S3: How connected equipment improves restaurant safety, service and sustainability.

Every restaurant facility manager is acutely aware of how critical their back-of-house equipment (cooking, refrigeration, HVAC, etc.) is as the lifeline of their operations. When these machines go down, or an issue arises, the result is often costly health or safety concerns that can force facility closures, negatively impact customer satisfaction, and harm brand perception. In addition, back-of-house equipment also drives the bulk of the very heavy energy use in restaurants — driving a significant cost on the business’s profits.

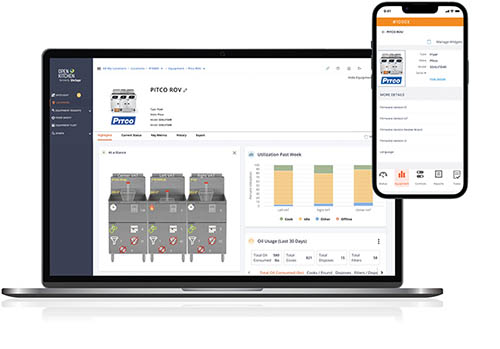

That’s why many facility managers are relying on a connected equipment strategy to improve their restaurants’ safety, service and sustainability, using technologies like the Internet of Things (IoT). By connecting critical equipment — HVAC, lights, freezers, refrigerators, ovens, dish machines and fryers — and accessing data on its performance from the cloud, managers are gaining remote, real-time oversight of their operations at hundreds, and even thousands, of restaurants simultaneously.

Using IoT to manage key equipment drives an “S3” strategy — Safety, Service and Sustainability — for multi-site foodservice operators. Facility managers can seamlessly maintain safer, more energy-efficient environments and provide better customer experiences, all while delivering millions of dollars in savings.

Here are just four of the ways that a well-connected equipment ecosystem is helping restaurants remain competitive in today’s marketplace:

1. Reduce energy costs while providing more comfortable facilities.

Technology enables comfortable environments in the most sustainable and cost-efficient ways possible. For example, one restaurant chain saved $20 million on energy by optimizing their equipment run times and operations.

• AI technology running on an IoT platform can autonomously coordinate the run times of HVAC equipment to reduce electricity demand charges for a facility, which are often 30% of an energy bill, while still maintaining a comfortable environment.

• Remote automated HVAC controls allow facility managers to maintain consistent temperature set points, keep guests and staff comfortable during business hours, and schedule temperature setbacks when buildings are unoccupied, reducing energy consumption.

• Cloud-connected systems can even proactively accommodate weather extremes, preventing such expensive disasters as frozen pipes. These new technologies provide systems that monitor local forecasts and automatically adjust heating and cooling equipment as needed to compensate.

2. Gain more control over food safety and quality.

The sensors in connected equipment monitor systems for mechanical issues. They also oversee equipment performance and call out any deviations from standard protocols. The foresight this data provides can prevent a wide variety of potentially catastrophic health and safety issues. It also ensures a universal application of best practices and enables consistently positive customer experiences. Some examples:

• One restaurant chain discovered their staff was cooking proteins before they were fully defrosted, making them unsafe for consumption. The restaurant caught the issue before the food was served and also stopped this poor procedure across multiple locations.

• IoT even allows restaurants with excellent safety records to identify issues. This was the case with one well-run multi-unit restaurant whose newly installed sensors caught more than 1,000 possible unsafe refrigeration conditions across its 200 locations, fortunately allowing them to be resolved before incidents occurred.

• Restaurants can universally monitor oil consumption in fryers so this expensive commodity can be filtered frequently enough to avoid distasteful flavors while still preventing over-disposal.

• Internet-connected ovens make it easy to achieve 100% compliance with new recipes and menus when a restaurant chain introduces a new food item or has a limited-time offer (LTO). Traditionally restaurants have undertaken the labor-intensive steps of distributing new recipes to hundreds of restaurants via thumb drives. Instead, IoT technology can disperse the recipes automatically to every connected oven in a restaurant chain. This automated approach delivers a consistent experience, assuring that a nationally advertised new food item is available and perfectly prepared at every location.

3. Optimize equipment performance to improve sustainability and reduce expenses.

Equipment breakdowns are not only expensive; they cause environmental challenges when, for example, freezers fail and cause food waste. The proactivity of connected equipment helps here, too, by recognizing problems before breakdowns occur. For example, when a connected oven has an issue, technicians receive a clearly defined error code, not only alerting them to the trouble in real-time, but also advising how to address the repairs. Because reactive maintenance can cost up to three times more than preventive measures, the ability to address fixes in a single visit instead of several contributes to significant savings for multi-site restaurants. One national brand recently saved over $1 million by adding an IoT-driven maintenance program to its 1,000-site chain.

4. Enhance guest service — and staff satisfaction.

All too often, the administrative responsibilities of running a foodservice operation can compete with the need to provide optimal guest service. IoT offsets this imbalance by automating administrative tasks, giving staff more opportunities to engage with customers and ensure their needs are met. The ability to deliver positive guest experiences also improves employee satisfaction by allowing staff to be more involved in the most important aspect of the restaurant’s business: the customer. What’s more, restaurants save thousands in annual labor costs.

Prove IoT Value by Overcoming One Pain Point at a Time

Restaurant facility managers typically find it straightforward to demonstrate the ROI of establishing a comprehensive IoT strategy. In fact, most restaurants see the investment in IoT strategies pay for itself within 1 year.

By addressing one pain point at a time, the latest technologies will begin to enhance a restaurant’s service excellence, enable safer environments and more easily meet sustainability goals. At the same time, they will boost an organization’s top and bottom lines. It’s no wonder that so many multi-chain restaurants are tapping IoT to improve their brand perception and maintain a competitive edge.

— Jay Fiske is president of Powerhouse Dynamics, a leading Internet of Things (IoT) solutions provider for eliminating waste in the operations of multi-site foodservice and retail facilities. Powerhouse’s IoT platform is connected with over 50,000 pieces of equipment across 15,000+ locations. Email: [email protected].