— By Alex Lundy —

When fryers are at the heart of a kitchen, complete oil management protects profits.

For restaurants where fried chicken, french fries, and other deep-fried dishes dominate the menu, fryer oil is not just an ingredient — it’s a cornerstone of the business. As one of the most significant recurring expenses, its management can directly impact both costs and customer satisfaction.

Despite inflation’s squeeze on operating budgets, cutting corners on fryer oil is a risky gamble. The freshness and quality of the oil are fundamental to the taste, texture, and safety of a restaurant’s flagship fried foods. Delaying oil changes in an attempt to save money can lead to subpar food quality, putting a restaurant’s reputation — and revenue — at risk. Customers notice when oil is overused. On the other hand, discarding oil prematurely across a large chain can lead to massive, unnecessary costs. For a restaurant with thousands of locations, even a small miscalculation in oil disposal can translate to millions of dollars lost annually.

The Role of Complete Oil Management

To optimize oil usage from delivery to disposal, restaurants are increasingly turning to complete oil management strategies. Leveraging Internet of Things (IoT) technologies, facility managers (FMs) can harness real-time data from commercial fryer controls and sensors via cloud-based analytics. This data-driven approach empowers FMs to pinpoint inefficiencies and implement proactive measures that protect profits while ensuring food quality.

Key insights from fryer oil analytics help FMs tackle critical challenges, including:

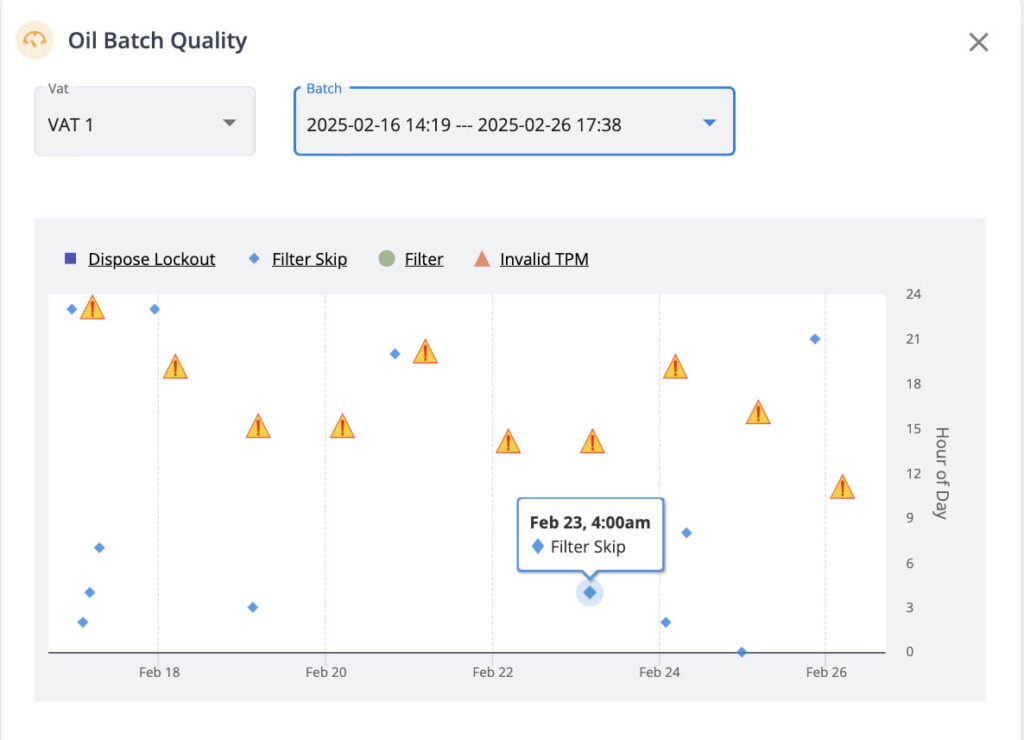

Skipped Oil Filtrations

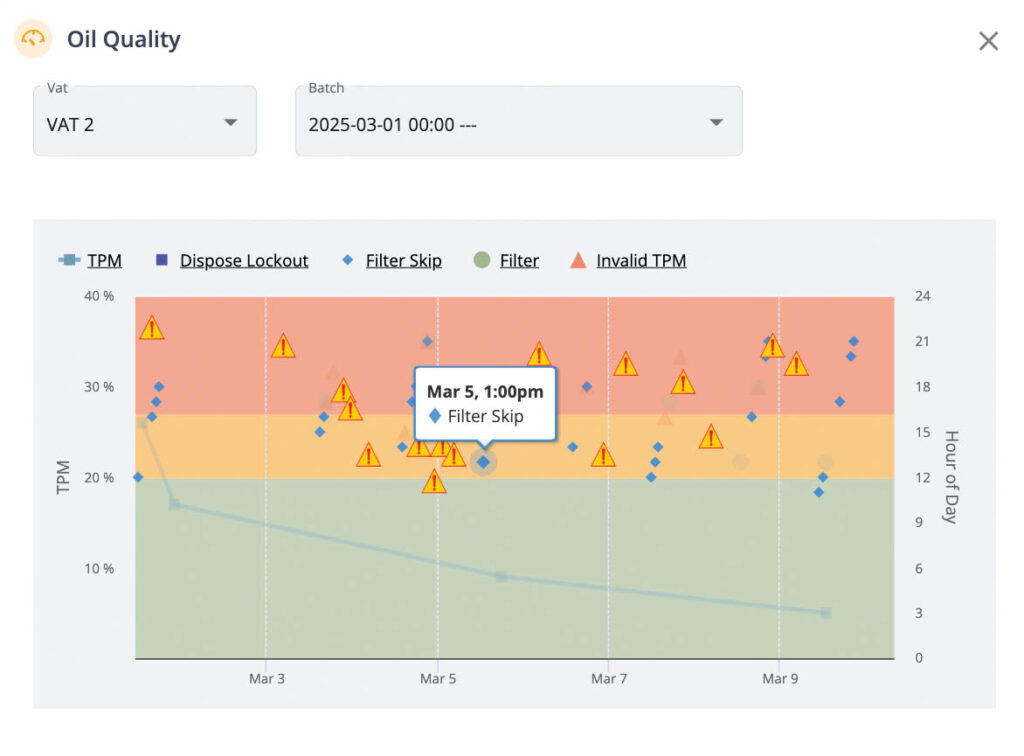

Multi-location restaurants establish clear standards for oil reuse, filtration, and disposal based on measured impurity levels (total polar materials – TPM). If the industry standard dictates disposal at a TPM reading of 20%, but certain locations repeatedly hit levels of 30% or higher, this signals that staff are neglecting proper filtration or disposal procedures. FMs can swiftly intervene by providing field leaders with actionable data to enforce compliance and maintain food quality.

Beyond cost savings, these insights can uncover broader issues. For instance, if a particular region reports declining customer satisfaction, poor quality oil might be contributing to the problem. TPM data can validate the issue, allowing managers to take corrective action before customer loyalty suffers.

Additionally, fryer oil analytics can expose operational red flags. In many locations, manually discarding fryer oil is one of the least favored tasks for kitchen staff. If employees claim they are performing oil changes while the data tells a different story, it could indicate deeper morale or accountability issues that management needs to address.

Premature Disposals

Conversely, real-time monitoring of TPM levels across thousands of fryers helps FMs identify locations where oil is being discarded too early. If data reveals that some restaurants are disposing of oil well before it reaches the recommended TPM threshold, management can step in and coach local teams on best practices. By ensuring oil is used to its optimal lifespan without compromising quality, restaurants can significantly reduce waste and operating costs.

Missed Maintenance

IoT-connected fryers also enable predictive maintenance. When fryers struggle to reach required temperatures or exhibit other performance issues, cloud-based systems trigger email alerts for local restaurant managers, prompting timely maintenance requests. FMs at the enterprise level gain visibility into these alerts, allowing them to spot regional patterns and address systemic maintenance gaps before they negatively impact service.

Maximizing the Value of Fryer Data

Beyond addressing these core challenges, FMs can further leverage oil and fryer analytics to drive enterprise-wide improvements:

• Streamlining Operations: Eliminating time-consuming manual spreadsheet tracking of TPM data ensures more accurate and complete records.

• Data-Driven Leadership: Monthly meetings with regional managers based on hard data foster informed decision-making, highlighting areas for improvement and recognizing top-performing locations.

• Enterprise-Wide Reporting: Quarterly reports provide leadership with clear, data-backed insights into oil management strategies, helping justify future investments in efficiency-enhancing initiatives.

• Investing in Smarter Equipment: New generations of connected fryers automate TPM readings and compare them with restaurant standards, making oil disposal decisions more precise. Some advanced models also integrate with bulk oil tanks, automatically pumping in fresh oil and safely disposing of used oil — eliminating the need for manual handling and enhancing both efficiency and safety.

Regardless of the specific equipment chosen, IoT-powered data is the key to unlocking greater efficiency, cost savings, and food quality in commercial kitchens. By harnessing fryer analytics, facility managers can make a lasting impact on profitability while ensuring that every fried dish meets the highest standards of excellence.

— Alex Lundy is vice president of product at Powerhouse Dynamics, the leading Internet of Things (IoT) solutions provider for eliminating waste in the operations of multi-site foodservice and retail facilities. Their IoT platform, sold under two different brands — Open Kitchen® for foodservice operators and SiteSage® for retail and other commercial operators — provides control over key equipment for reduced waste and increased cost savings, actionable insights for more informed decisions on equipment and operations, and improved processes for consistent, positive experiences in their facilities. The platform is connected with over 50,000 pieces of equipment across 15,000+ locations. Contact the author at [email protected].