— By Ramez Naguib —

Exploring the benefits of glycol chillers in restaurants.

Glycol chillers are specialized refrigeration systems and often involve the use of antifreeze. A popular application is in beverage production, wherein the food grade chemical propylene glycol is used.i

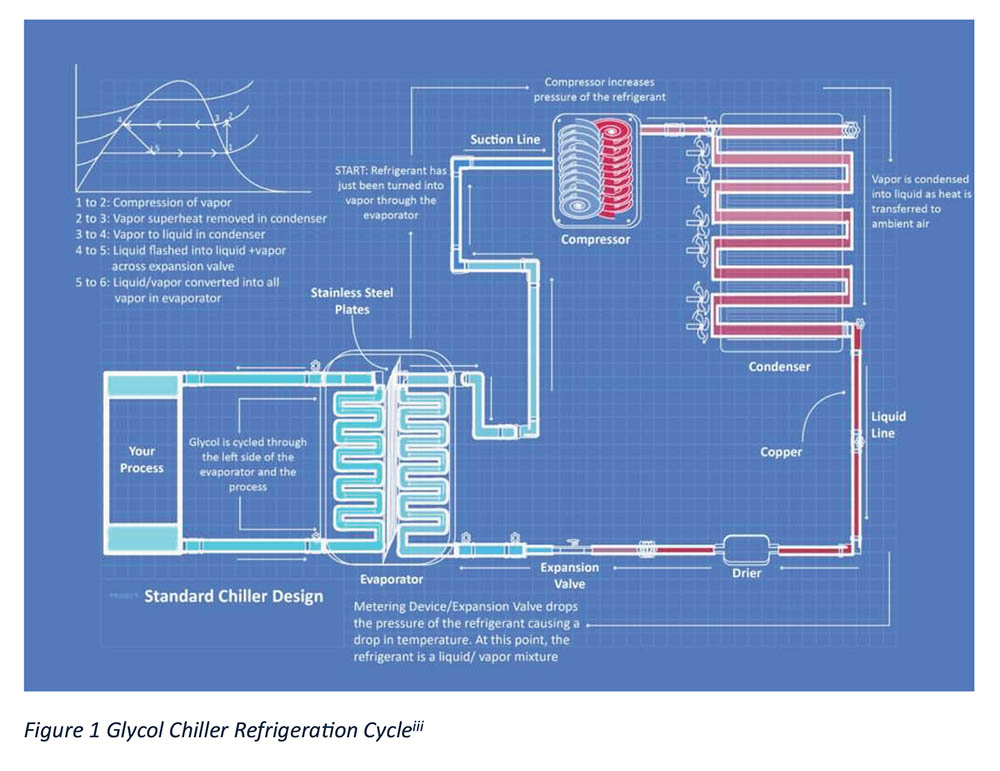

Glycol is not a refrigerant; instead, it is a fluid that is used to carry heat from one location to another in much the same way as a conventional refrigerant does. But, unlike a refrigerant, glycol does not undergo a state change (from a liquid to a gas, or vice versa) the way refrigerants typically do.

Secondary refrigeration systems like glycol also represent one of the good approaches adopted in response to the movement toward less environmentally harmful refrigerants. The idea behind them is to limit the amounts of synthetic refrigerants used in a system.

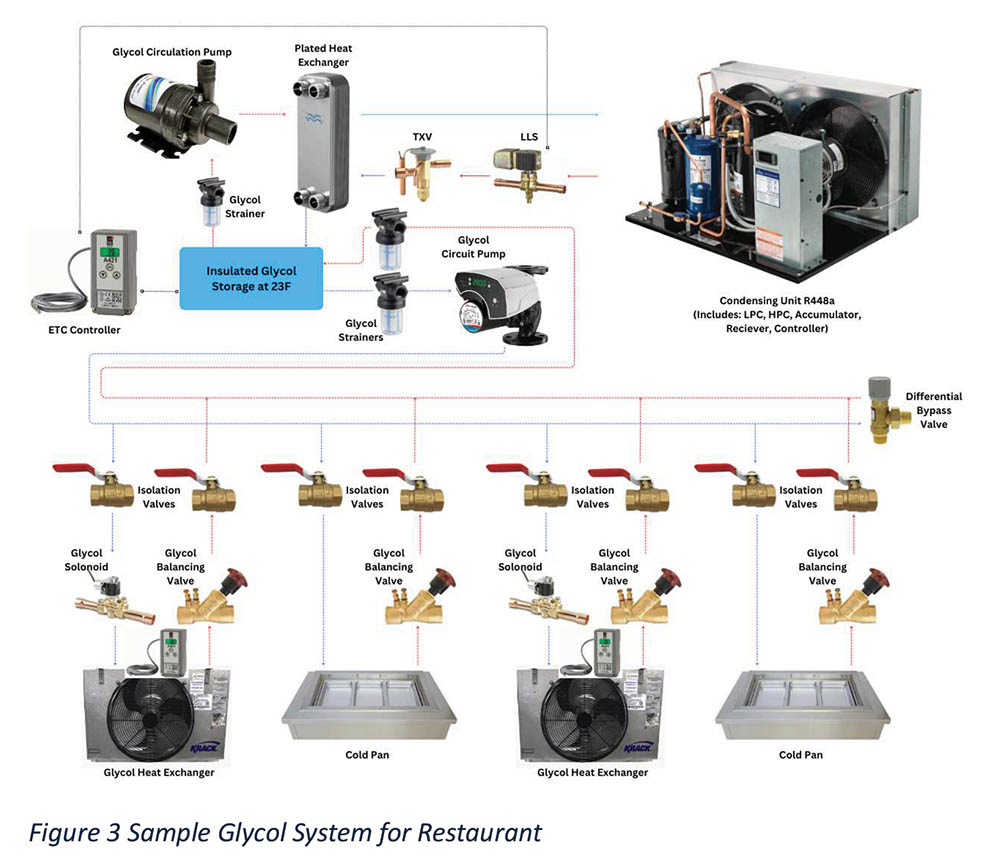

A major advantage of secondary systems over traditional systems is that with them, users can significantly reduce the amounts of refrigerant needed for them to operate. Secondary systems are typically designed so that only a heat transfer fluid is circulated through the restaurant’s piping to its refrigerated cases, coolers and freezers. The only refrigerant used in the system is strictly confined to the primary side which only circulates the refrigerant through piping between the refrigeration rack (on which the compressors, heat exchangers and other equipment sit) and the condensers usually outside of the building. Taking this approach requires only a fraction of the amount of refrigerant that would otherwise be needed in a traditional system.ii

What is a Glycol Chiller?

Glycol chillers are a specific kind of refrigeration system, often used to cool a variety of liquids, including alcohol and other beverages. Using a chiller allows producers to lower the temperature of the product dramatically over a short period of time, depending on the production needs. Propylene glycol plays a significant role in the application of a glycol chiller. For cooling in brewing, there are few processes where decreasing or maintaining temperature are important — like crash cooling a beer after fermentation or keeping a steady temperature during fermentation (which generates heat) or cooling the wort after an initial boiling process.iv

Advantages of Glycol Chillers

• Initial glycol chiller system investment can be less than self-contained refrigeration, since it involves purchasing one glycol chiller unit versus numerous smaller units.

• Smaller units also take up significant kitchen space with compressor cabinets that require “breathing room.”

• Rooftop placement of the chiller reduces or eliminates the number of high-failure parts inside the kitchen and allows maintenance and repair to be done without disrupting food preparation or kitchen service.

• Optional heat reclaim technology allows heat removed from the chilled fixtures to be recycled and used to heat kitchen water. This technology keeps the boiler from working as hard to heat water, which saves energy instead of wasting it into the ambient air.

• Finally, the lifetime usage of the glycol chiller system is expected to double — up to 20 years compared to 10 years for the previous system.v

Propylene Glycol

Propylene glycol is used by the chemical, food and pharmaceutical industries as an antifreeze when leakage might lead to contact with food. The Food and Drug Administration (FDA) has classified propylene glycol as an additive that is “generally recognized as safe” for use in food.

Propylene glycol is a clear, colorless, slightly syrupy liquid at room temperature. It may exist in air in the vapor form, although propylene glycol must be heated or briskly shaken to produce a vapor. Propylene glycol is practically odorless and tasteless.vi

Conclusion

In summary, glycol chillers represent a forward-thinking refrigeration solution for restaurants, particularly in light of the industry’s drive toward sustainability. By employing propylene glycol, a food-safe antifreeze, as a heat transfer fluid in a secondary refrigeration system, these chillers significantly reduce the reliance on traditional synthetic refrigerants, aligning with environmental best practices. Beyond the environmental benefits, glycol chillers offer practical advantages such as potentially lower initial investment costs for an entire system compared to numerous smaller units, space savings in the kitchen and the ability to locate the chiller remotely (e.g., on a rooftop) to minimize disruption during maintenance. Furthermore, the option for heat reclaim technology to heat kitchen water and the expected doubling of system lifespan to 20 years underscore the long term operational and cost efficiencies that make glycol chillers a compelling choice for modern restaurant refrigeration.

— Ramez Naguib, P.E. is president of Clima-Tech LLC, a leading provider of refrigeration and HVAC maintenance and installation services in Los Angeles. TradeWind Chillers is a subsidiary of Clima-Tech.

NOTES:

i https://en.wikipedia.org/wiki/Glycol_chiller

ii Hillphoenix, https://www.hillphoenix.com/services/learning-center/glycol-refrigerant/

iii www.chiller.com

iv The Brewers Association’s Guide to Starting Your Own Brewery by Dick Kentwell

v Swanson, J. 2016, Glycol Improves Efficiency, Reduces Maintenance Costs for Restaurant Kitchens. Trane

vi National Center for Biotechnology Information (2024). PubChem Compound Summary for CID 1030, Propylene Glycol. Retrieved November 28, 2024 from https://pubchem.ncbi.nlm.nih.gov/compound/Propylene-Glycol